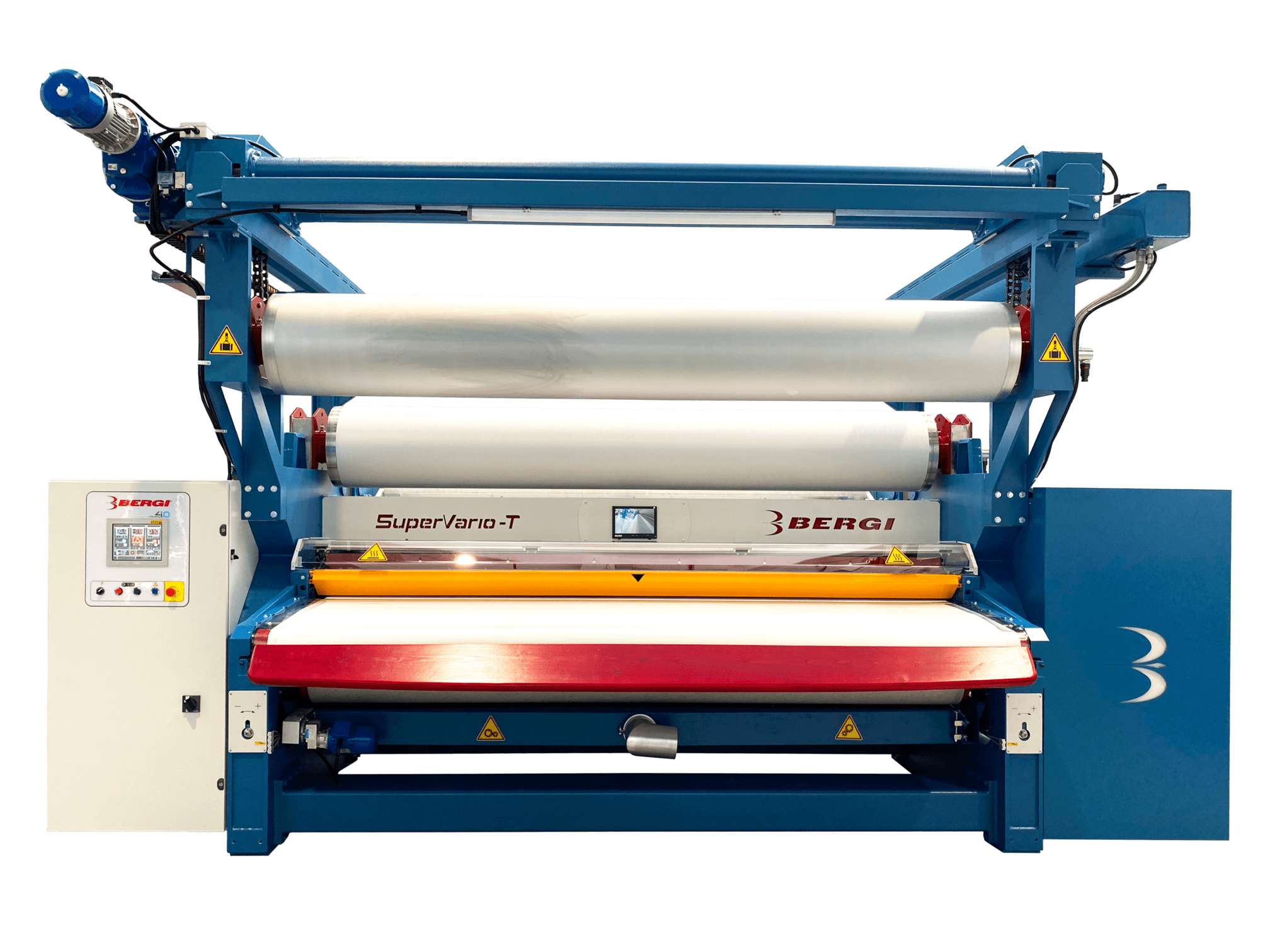

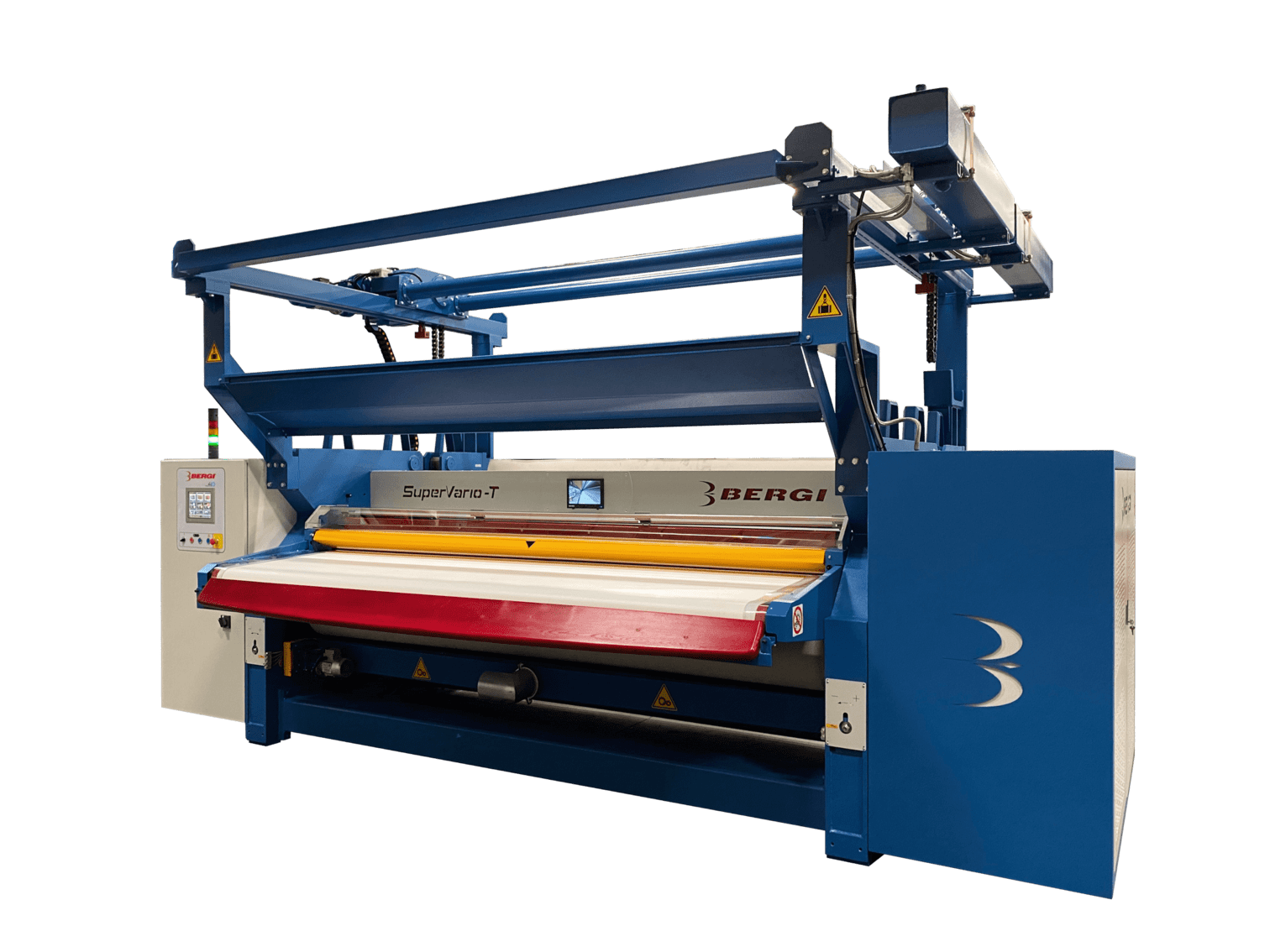

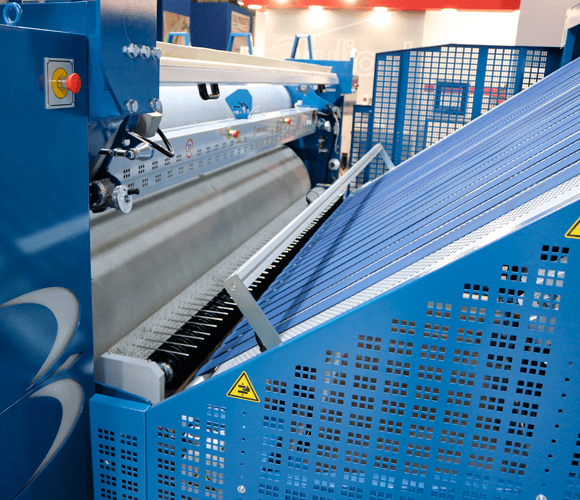

Is the top of the range through-feed ironing and embossing machine, ideal for shoe uppers, leather goods, upholstery and car interiors.

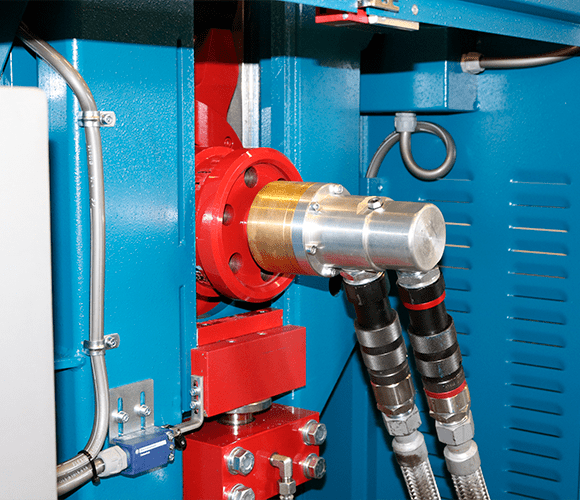

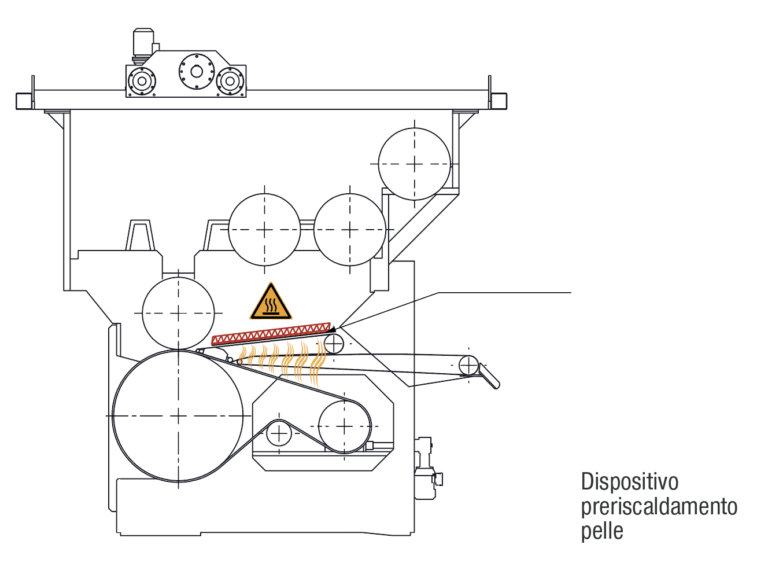

It has the leather pre-heating system as standard and a wider under-pressure contact between the operative roller and the leather.

Its technical characteristics place it at the top of its category, as it is closer to the result of a plate press.