Back to: Embossing machines

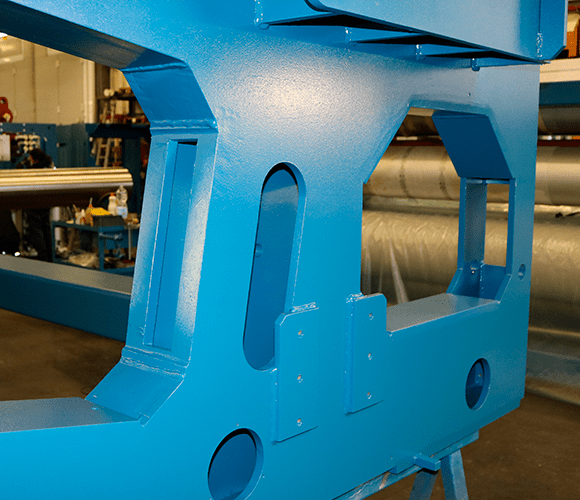

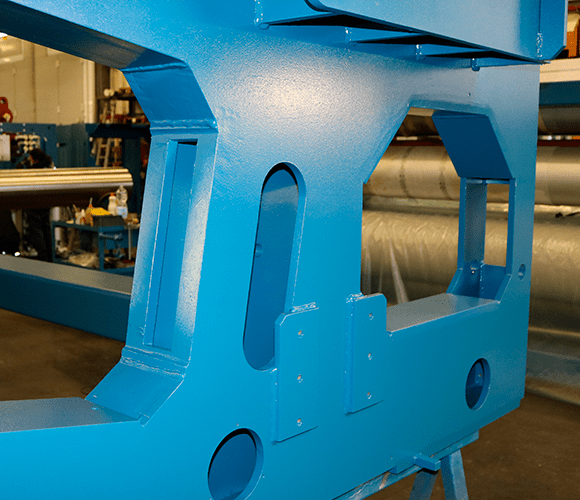

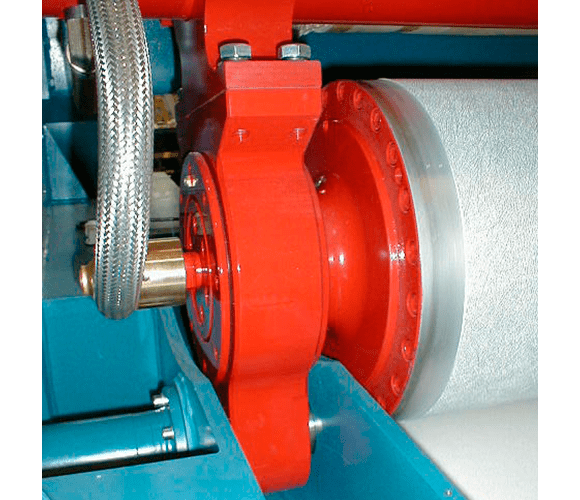

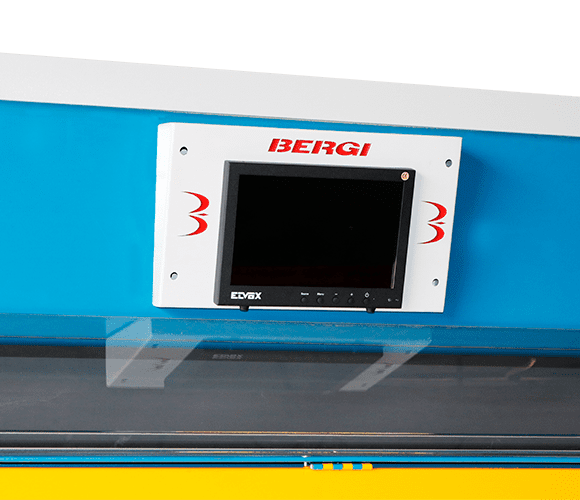

Heavy duty through-feed press for ironing and embossing with automatic revolver-type roller changing device.

Through-feed press for ironing and embossing at high work pressures. It has an automatic roller changing system with revolver device and an independent heating unit for each roller. It can store up to 3 large diameter operative rollers.

Sizes: 1800 / 2200 / 2600 / 3100 / 3200 / 3400

| MODEL | SUPERSTAR | 18 | 22 | 26 | 31 | 32 | 34 |

|---|---|---|---|---|---|---|---|

| Effective width | mm | 1800 | 2200 | 2600 | 3100 | 3200 | 3400 |

| Working speed | m/min | 3÷14 | 3÷14 | 3÷14 | 3÷14 | 3÷14 | 3÷14 |

| Working pressure | Kg/cm | 50-250 | 50-250 | 50-250 | 50-250 | 50-250 | v |

| Maximum working temperature | °C | 0-160 | 0-160 | 0-160 | 0-160 | 0-160 | 0-160 |

| Installed power with operator roll | kW | 24 | 24 | 29 | 34 | 34 | 36 |

| Additional heating system for an operator roll | KW | 16.5 | 16.5 | 21.5 | 2626.5 | 26.5 | 27 |

| Preheating power | kW | 10 | 10 | 10 | 10 | 10 | 10 |

| Net weight of machine with operator roll | Kg | 9800 | 10800 | 12200 | 12600 | 13000 | 13500 |

| Net weight of an operator roll | Kg | 1100 | 1300 | 1900 | 2300 | 2500 | 2700 |

| Base model dimensions Superstar N | mm | 4140 x 2150 x 2500 h | 4540 x 2150 x 2500 h | 4940 x 2150 x 2500 h | 5440 x 2150 x 2500 h | 5540 x 2150 x 2500 h | 5740 x 2150 x 2500 h |

| Superstar S | mm | 2600 h | 2600 h | 2600 h | 2600 h | 2600 h | 2600 h |

| Preheating temperature * | °C | 0-110 | 0-110 | 0-110 | 0-110 | 0-110 | 0-110 |

| Preheating power * | kW | 10 | 10 | 10 | 10 | 10 | 10 |

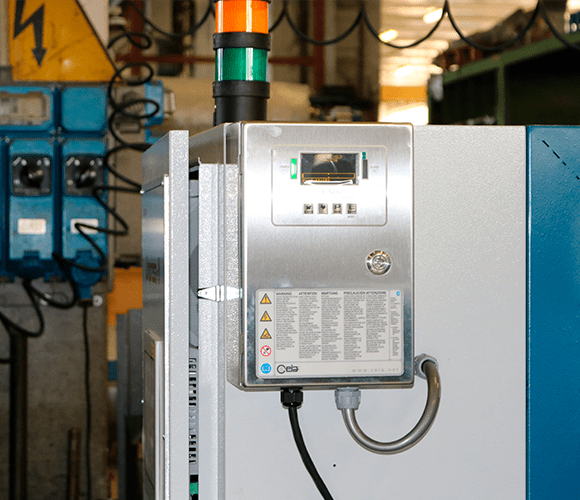

Aware of its responsibilities, Bergi joined the “Supplier of Sustainable Technologies” project promoted by Assomac in 2017, with the aim of contributing to deepening the key issues related to the intelligent and conscious management of energy, water, and natural resources, with the perspective of qualifying the manufacturing industry’s production process as sustainable.

The focal point of the project is the “Green Label,” a voluntary declaration certifying the energy and environmental performance of machines, calculated based on internationally recognized parameters such as the CFP (Carbon Footprint, the amount of equivalent carbon dioxide emissions) measured using the shared and standardized Life Cycle Assessment (LCA) calculation methodology.

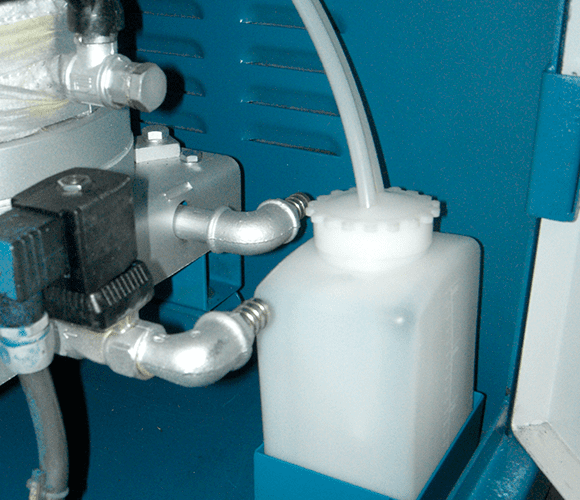

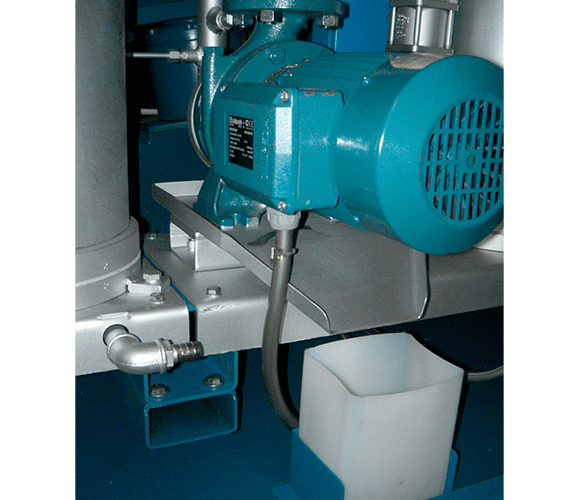

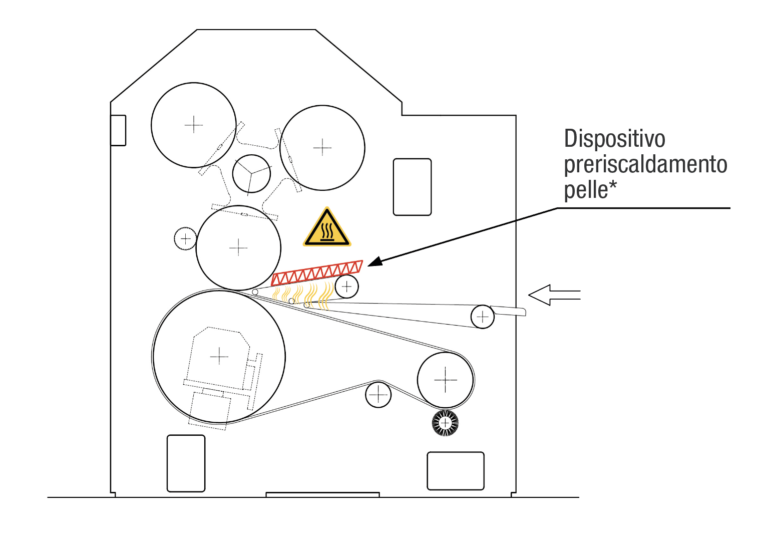

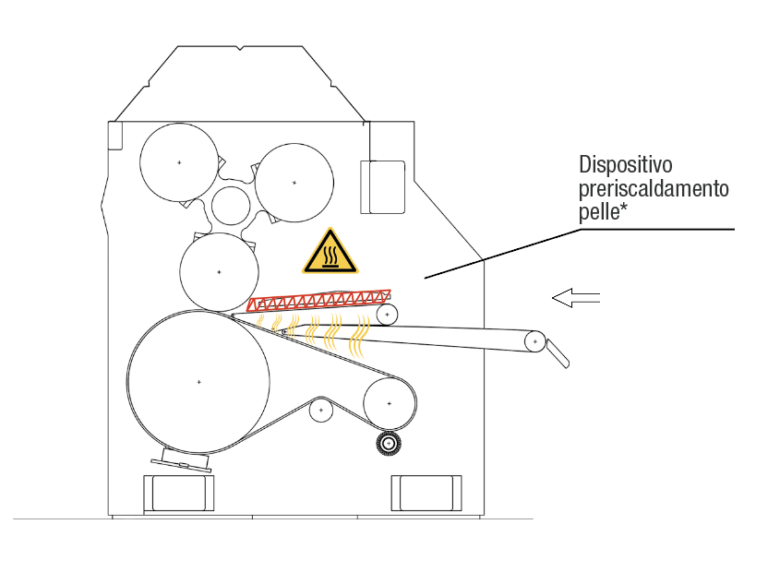

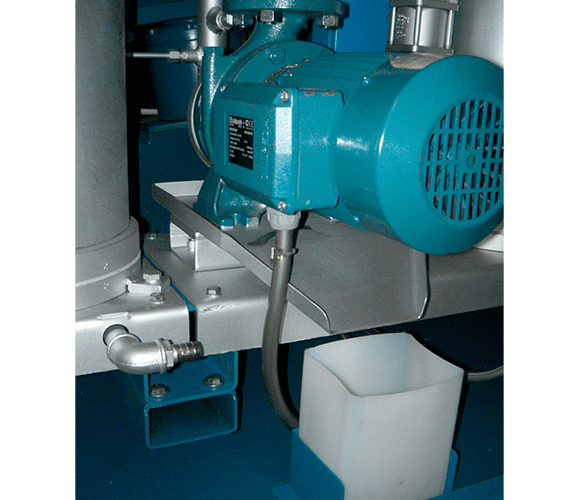

It's an accessory to be paired with the continuous press for printing with a winch, where at rest, there are rollers that need to be preheated before the change. This way, when the operator roller is changed, it's already at the desired temperature without any time loss. The heater is equipped with wheels and can be moved from one machine to another. It comes with an electrical system and is fully autonomous. It can reach temperatures of up to 160°C.

Top heavy duty through-feed press for ironing and embossing with automatic revolver-type roller changing device. It has an automatic roller changing system with revolver device and an independent heating unit for each roller.

Compared to the standard Superstar, it has the leather pre-heating system as standard and a wider under-pressure contact between the operative roller and the leather. Its technical characteristics place it at the top of its category, as it is closer to the result of a plate press.

Sizes: 1800 / 2200 / 2600 / 3100 / 3200

| MODEL | SUPERSTAR T | 18 | 22 | 26 | 30 | 32 | 34 |

|---|---|---|---|---|---|---|---|

| Useful Width | mm | 1800 | 2200 | 2600 | 3000 | 3200 | 3400 |

| Working Speed | m/min | 3-14 | 3-14 | 3-14 | 3-14 | 3-14 | 3-14 |

| Working Pressure | Kg/cm | 50-350 | 50-350 | 50-350 | 50-350 | 50-350 | 50-350 |

| Working Temperature | C° | 0-160 | 0-160 | 0-160 | 0-160 | 0-160 | 0-160 |

| Preheating Temperature | C° | 0-110 | 0-110 | 0-110 | 0-110 | 0-110 | 0-110 |

| Installed Power with one operator roll | kW | 32 | 32 | 43 | 43 | 43 | 43 |

| Additional Heating Plant for each operator roll | kW | 16 | 16 | 26 | 26 | 26 | 26 |

| Installed Power for preheating | kW | 10 | 10 | 10 | 10 | 10 | 10 |

| Net weight of machine with one operator roll | kg | 9500 | 11100 | 11500 | 12000 | 14000 | 14600 |

| Net weight of an operator roll | kg | 1100 | 1400 | 1900 | 2300 | 2500 | 2700 |

| Basic model dimensions | mm | 4150x 2650x 25300h | 4550x 2650x 25300h | 4950x 2650x 25300h | 5350× 2650x 25300h | 5550x 2650x 25300h | 5750x 2650x 25300h |

Aware of its responsibilities, Bergi joined the “Supplier of Sustainable Technologies” project promoted by Assomac in 2017, with the aim of contributing to deepening the key issues related to the intelligent and conscious management of energy, water, and natural resources, with the perspective of qualifying the manufacturing industry’s production process as sustainable.

The focal point of the project is the “Green Label,” a voluntary declaration certifying the energy and environmental performance of machines, calculated based on internationally recognized parameters such as the CFP (Carbon Footprint, the amount of equivalent carbon dioxide emissions) measured using the shared and standardized Life Cycle Assessment (LCA) calculation methodology.

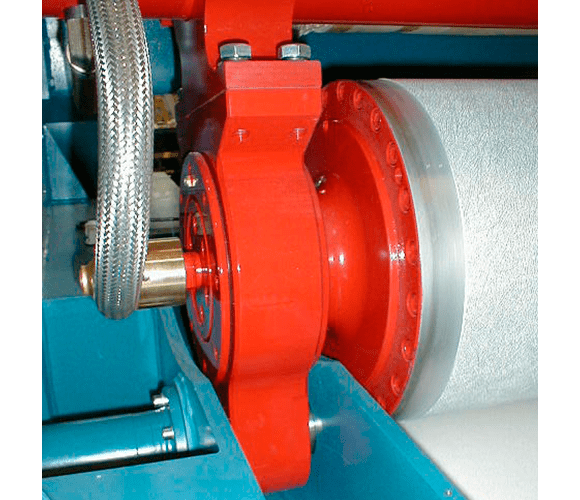

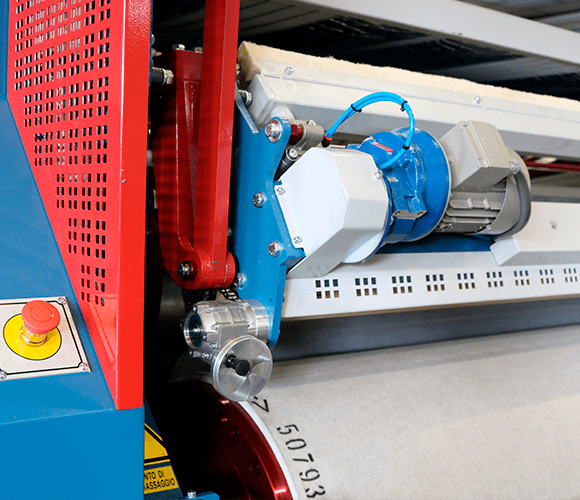

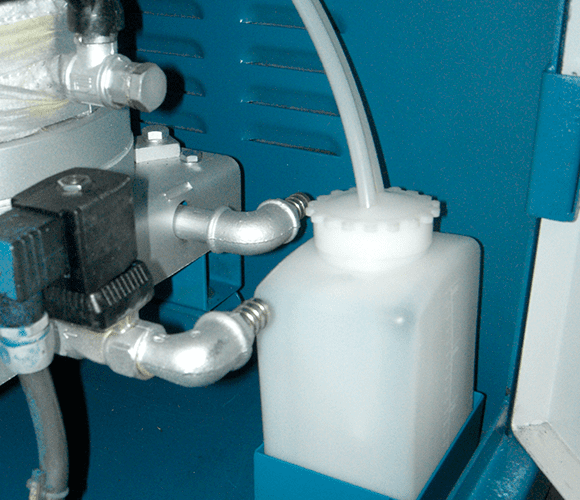

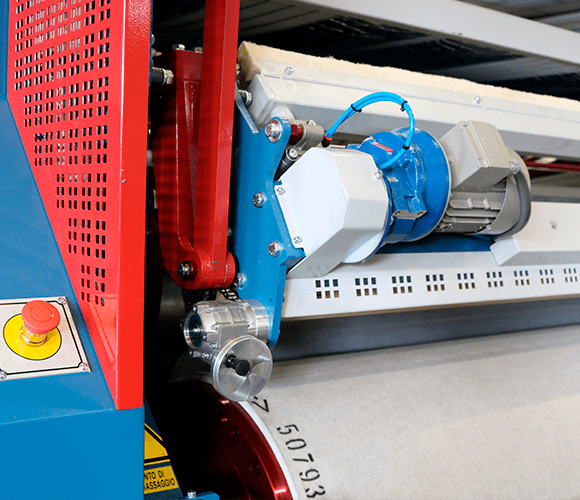

For working with pressure or open thickness with the synchro motorized operative roller.

Bergi S.p.A.

Via Montorso 4/A,

36071 Arzignano, VI, Italy

CF/P.IVA 01277430243

REA VI-158023

Reg. Imp. VI-01277430243

M. VI-005517

Cap. soc. € 1.000.000,00 int. vers.

© 2024 Bergi S.p.A. | All Rights Reserved