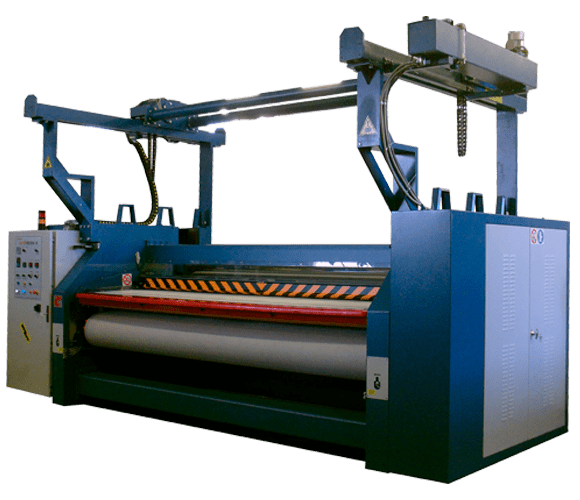

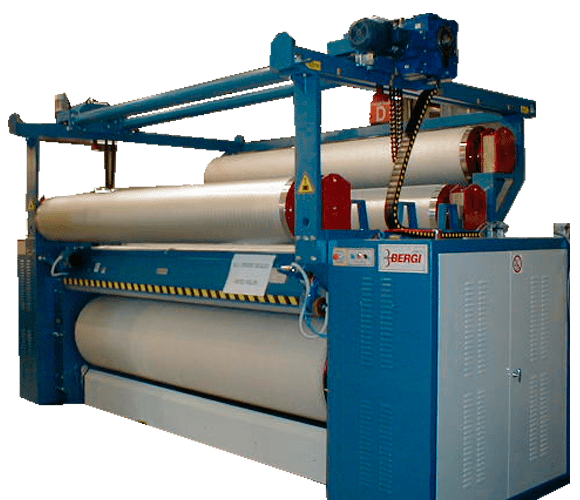

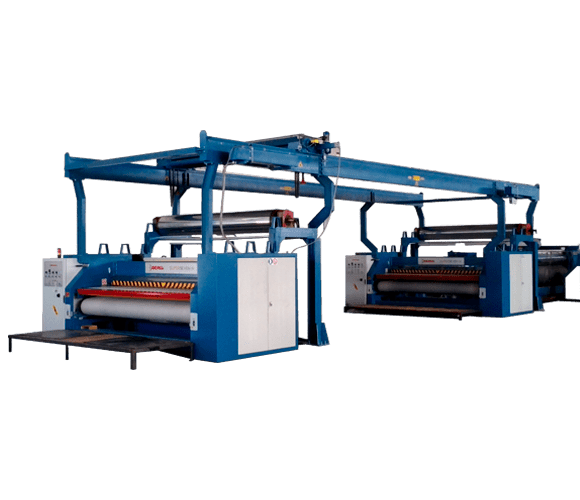

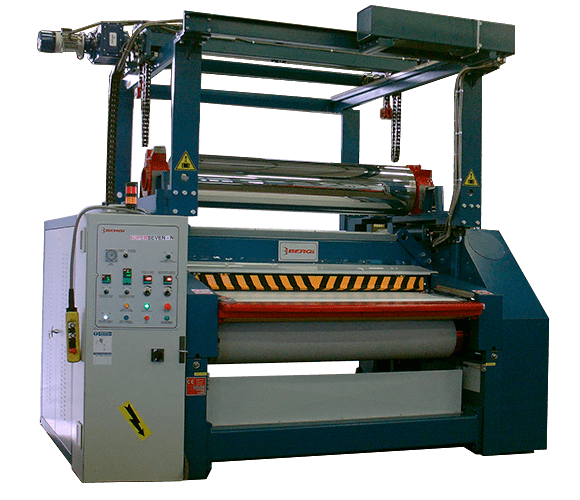

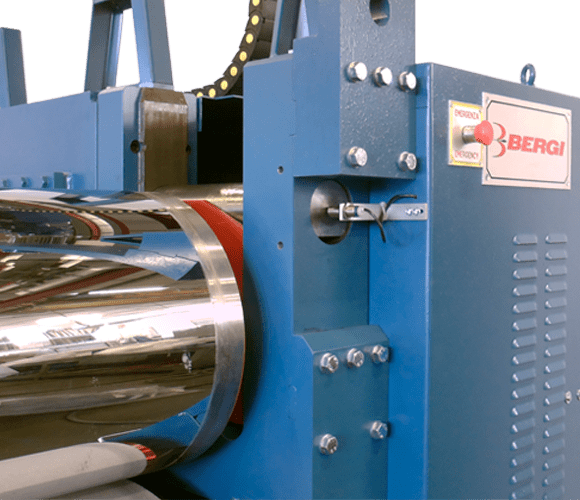

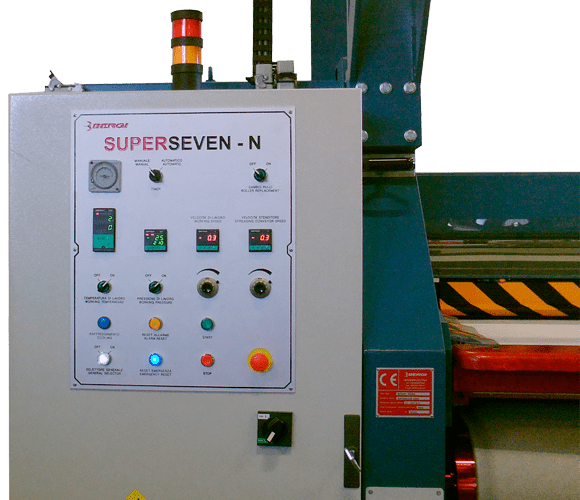

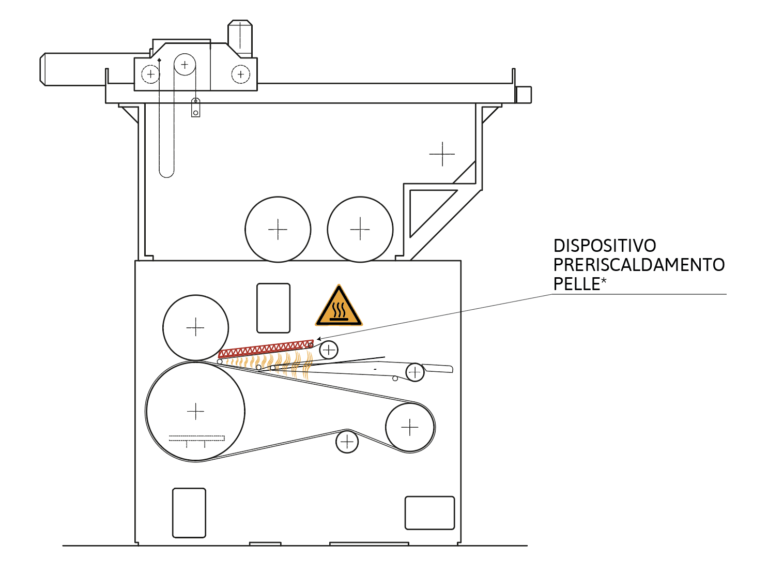

Superseven is the ideal through-feed rotative press for ironing and embossing shoe uppers, leather goods and upholstery leathers at medium and high pressures.

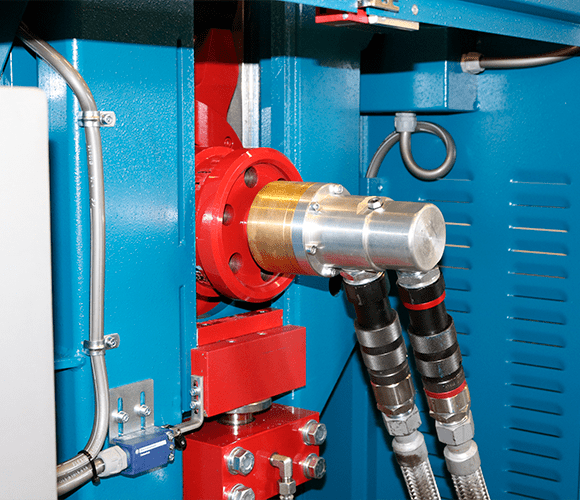

It has been designed to be a useful productive instrument for those who need to iron with high pressures and emboss from hair-cell to medium/heavy grains at regular speeds.

It is excellent in value for money, with high performance characteristics.