Back to: Embossing machines

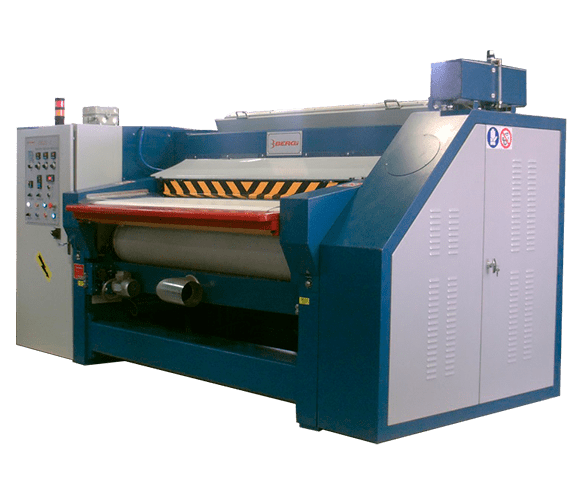

Through-feed press for ironing and satin-finishing.

Finilux is the through-feed ironing machine normally used in finishing to enhance the glossy effect of the finish, whose characteristics make it ideal for processing small or medium sized leathers, up to whole bovine leathers.

The basic version is the traditional machine for ironing, glazing and engraving of light prints. It can work up to a pressure of 130 Kg/cm.

Sizes: 1800 / 2200 / 2600 / 3200 FINILUX TR: 1800 / 3200

| MODEL | FINILUX | 18 | 22 | 26 | 32 |

|---|---|---|---|---|---|

| Usable Width | mm | 1800 | 2200 | 2600 | 3200 |

| Working Speed | m/min | 4 ÷ 18 | 4 ÷ 18 | 4 ÷ 18 | 4 ÷ 18 |

| Total Power | kW | 21 | 22 | 30 | 30 |

| Working Pressure | Kg/cm | 130 | 130 | 130 | 130 |

| Working Temperature | °C | 0-160 | 0-160 | 0-160 | 0-160 |

| Net Weight of Base Model | Kg | 4100 | 4600 | 5500 | 6750 |

| Base Model Dimensions | mm | 3300 x 1780 x 1650 h | 3700 x 1780 x 1650 h | 4000 x 1780 x 1650 h | 4700 x 1780 x 1650 h |

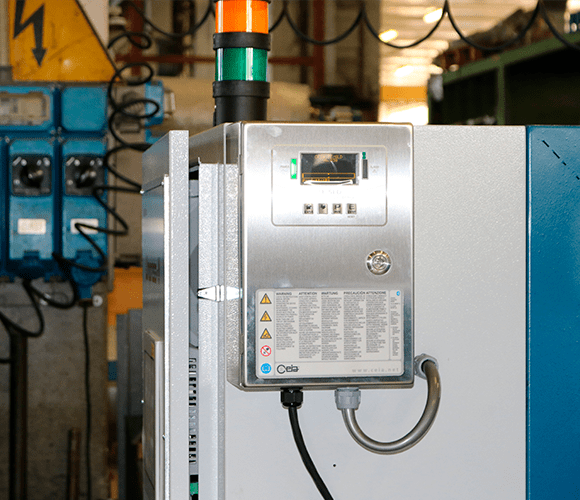

Aware of its responsibilities, Bergi joined the “Supplier of Sustainable Technologies” project promoted by Assomac in 2017, with the aim of contributing to deepening the key issues related to the intelligent and conscious management of energy, water, and natural resources, with the perspective of qualifying the manufacturing industry’s production process as sustainable.

The focal point of the project is the “Green Label,” a voluntary declaration certifying the energy and environmental performance of machines, calculated based on internationally recognized parameters such as the CFP (Carbon Footprint, the amount of equivalent carbon dioxide emissions) measured using the shared and standardized Life Cycle Assessment (LCA) calculation methodology.

FINILUX S

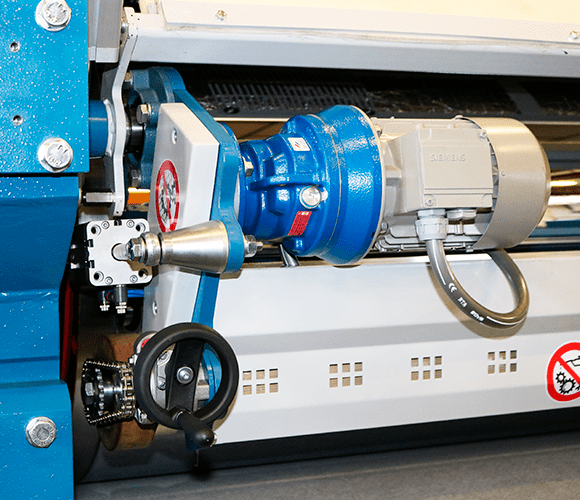

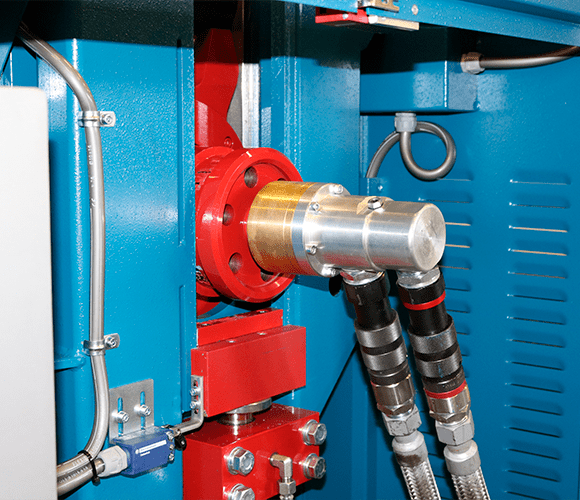

Ideal machine for ironing by pressure or alternatively by thickness, for ironing only the peaks of heavy grains or ironing leathers without crushing the fibres, keeping them soft. The machine can work up to a pressure of 130 kg/cm. The motorized roller, which works the leather in synchro, allows thickness ironing and provides a very light touch on the leather surface without crushing it. The model S is the ideal to give a brilliant effect to the peaks of the embossed leathers and leave the underlying part opaque.

FINILUX TR

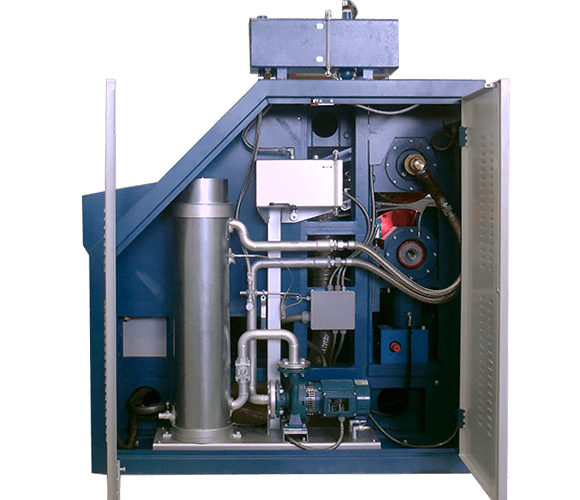

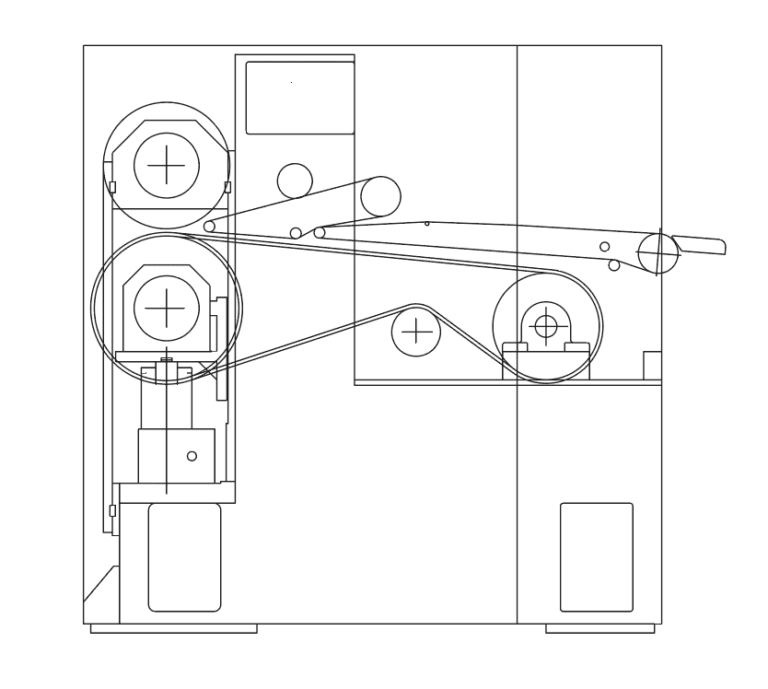

Special machine for the application of glossy, matte, laminated, sequined, patterned transfers to leather. The system is equipped with an accessory for protecting the felt with a reel of film. Normally a polyester film is used.

On the front part of the machine there is a transfer film unwinding device, which can be single or multiple (1, 2 or 4 reels), with a spreading roller that keeps the film well stretched. The detachment area, in the rear side, is compete with cooling device. Customized solutions are applied as required.

With the Finilux TR properly equipped, it is now possible to apply the finishing on full grain or buffed grain, by thermal transfer from polyester film or embossed release paper. If the working pressure is low and the machine is only used for finishing with release paper, a belt with siliconized surface can be used instead of using the felt protection kit.

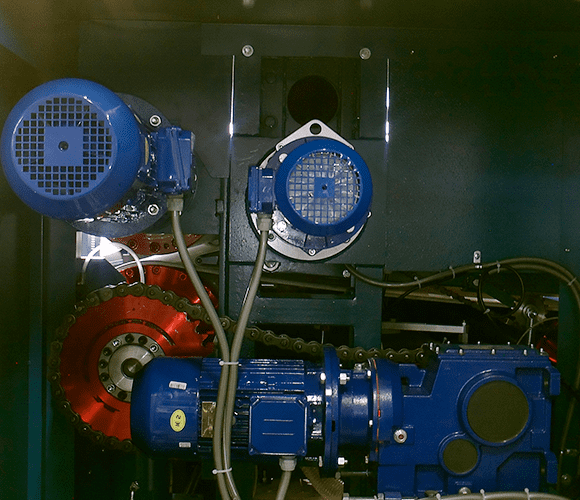

It's an accessory to be paired with the continuous press for printing with a winch, where at rest, there are rollers that need to be preheated before the change. This way, when the operator roller is changed, it's already at the desired temperature without any time loss. The heater is equipped with wheels and can be moved from one machine to another. It comes with an electrical system and is fully autonomous. It can reach temperatures of up to 160°C.

Bergi S.p.A.

Via Montorso 4/A,

36071 Arzignano, VI, Italy

CF/P.IVA 01277430243

REA VI-158023

Reg. Imp. VI-01277430243

M. VI-005517

Cap. soc. € 1.000.000,00 int. vers.

© 2024 Bergi S.p.A. | All Rights Reserved