Back to: Automation and handling

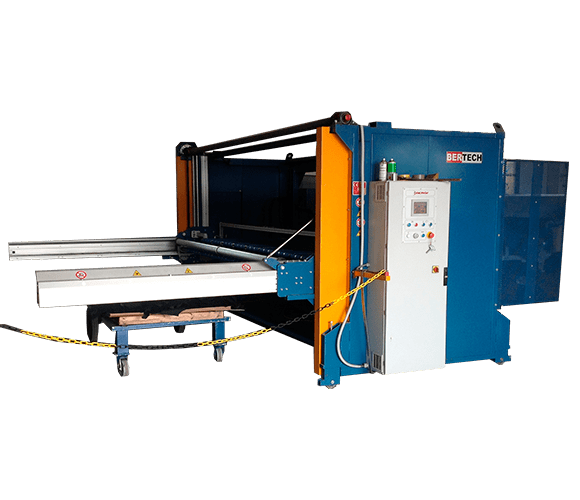

Compact Traditional Stacker.

The BERTECH DYNAMIC stacker is built in two versions: one specific for the wet area and one for the dry area.

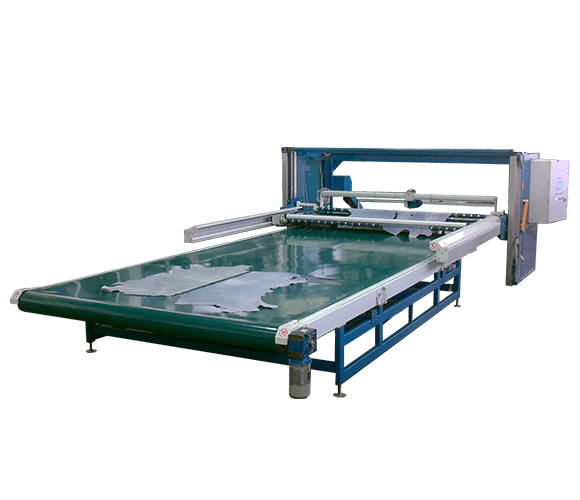

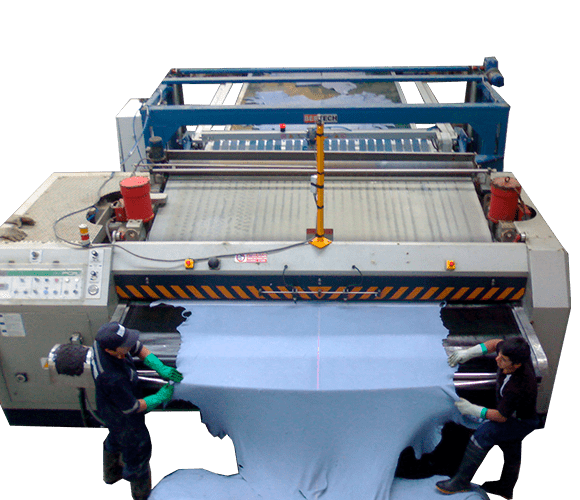

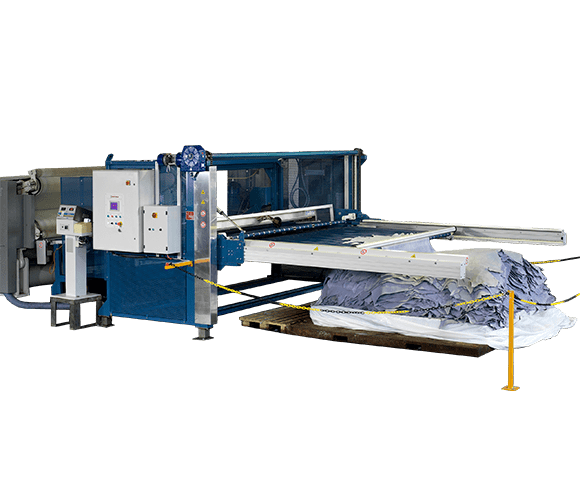

Built with high-quality materials, it has a solid and robust structure and is composed of components designed for use in tanneries. Its compact dimensions place it among the shortest in its category, while still featuring an inclined conveyor belt ramp ideal for any type of hide, without problems of rolling or slipping. BERTECH is the only manufacturer that equips its stackers, DYNAMIC and ARMLESS, as standard with the fall arrest system for the lifting group, an essential component for the total safety of the machine. Another feature that sets it apart is the usable working width, which is always equal to or greater than that described in the catalog.

With DYNAMIC, you can easily handle any type of hide for the following operations:

The stacker is available in five versions:

XS = extra short: for ovine/caprine hides (carriage rope length 1600 mm);

S = short: for stacking onto a horse and table (carriage rope length 2000 mm);

M = medium: for stacking onto a horse, table, or pallet, for short hides (carriage rope length 2800 mm);

L = long: for stacking on any support (carriage rope length 3100 mm);

XL = extra long: for hides over 55 feet on any support (carriage rope length 3300 mm).

Size: 2000/2200/2600/3200/3400/3600

| MODEL | DYNAMIC | 20 | 22 | 26 | 32 | 34 |

|---|---|---|---|---|---|---|

| Installed Power | kW | 3.35 | 3.35 | 3.95 | 3.95 | 3.95 |

| Machine Weight | kg | 1950 | 2050 | 2200 | 2300 | 2400 |

| Overall Dimensions | mm | 3410 x 6000 x 2400 h | 3650 x 6000 x 2400 h | 4090 x 6000 x 2400 h | 4610 x 6000 x 2400 h | 4850 x 6000 x 2400 h |

| Transport Dimensions | mm | 3320 x 2170 x 2300 h | 3650 x 6000 x 2400 h | 4000 x 2170 x 2300 h | 4520 x 2170 x 2300 h | 4760 x 2170 x 2300 h |

Bergi S.p.A.

Via Montorso 4/A,

36071 Arzignano, VI, Italy

CF/P.IVA 01277430243

REA VI-158023

Reg. Imp. VI-01277430243

M. VI-005517

Cap. soc. € 1.000.000,00 int. vers.

© 2024 Bergi S.p.A. | All Rights Reserved