Back to: Roller coating machines

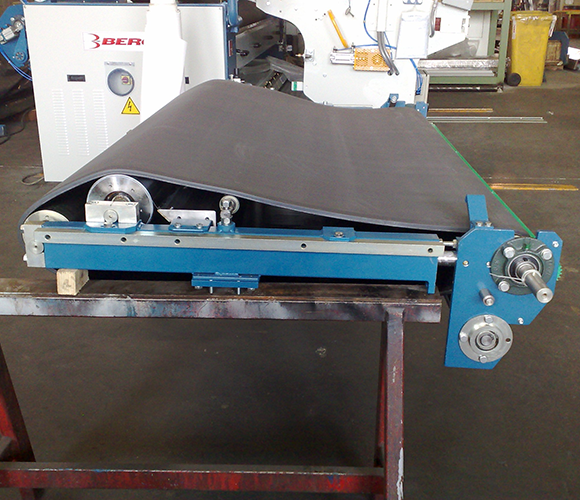

Traditional roller infill machine.

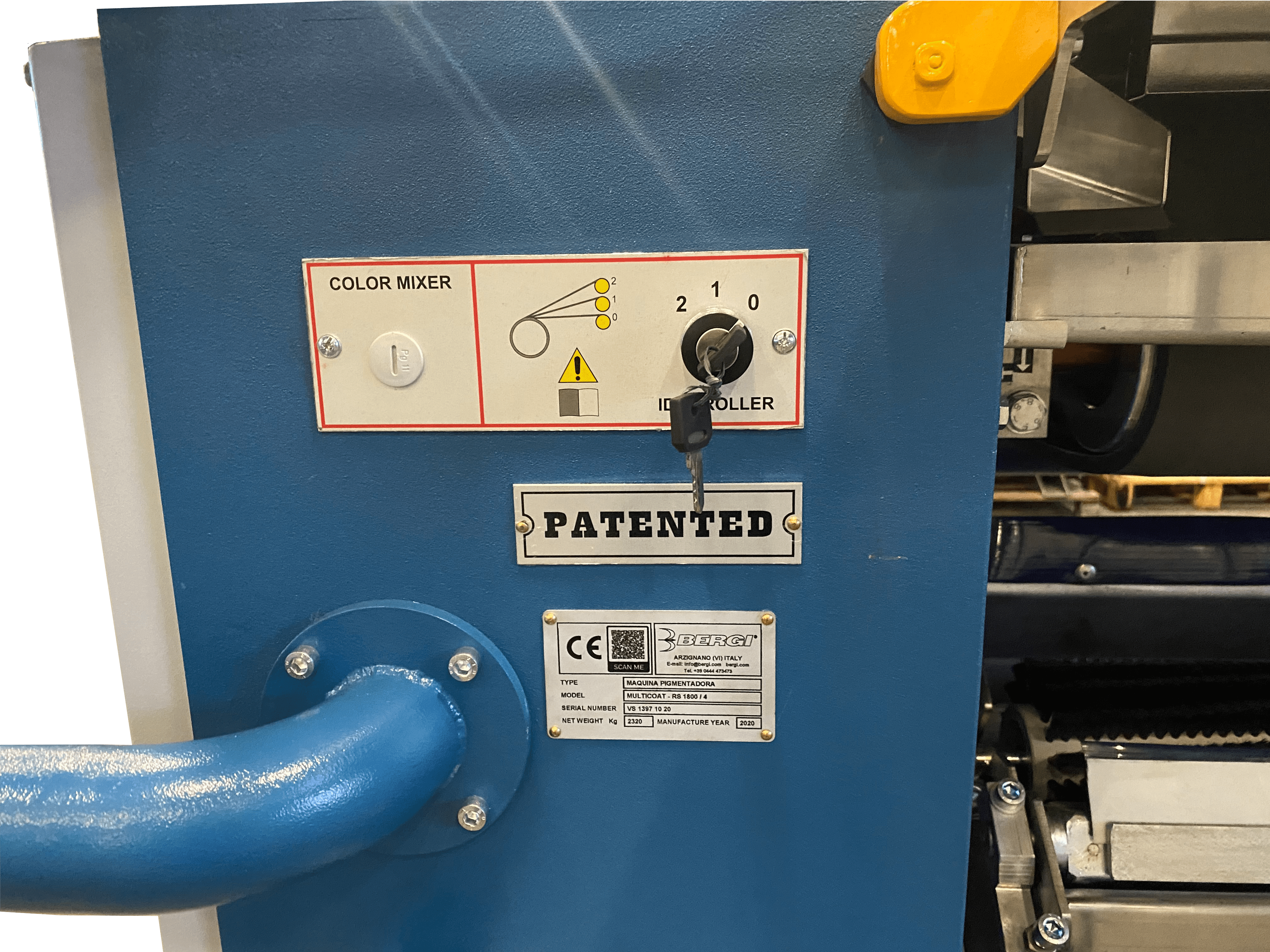

The Multicoat roller padder is the latest version of BERGI S.p.A.’s traditional pigmenting machine.

Completely redesigned, the Multicoat is the result of many years of experience in the field of application, which began back in 1985.

In developing this new model, a lot of work has been done to achieve a machine that is simple to use yet highly versatile, to accompany the user in various work processes.

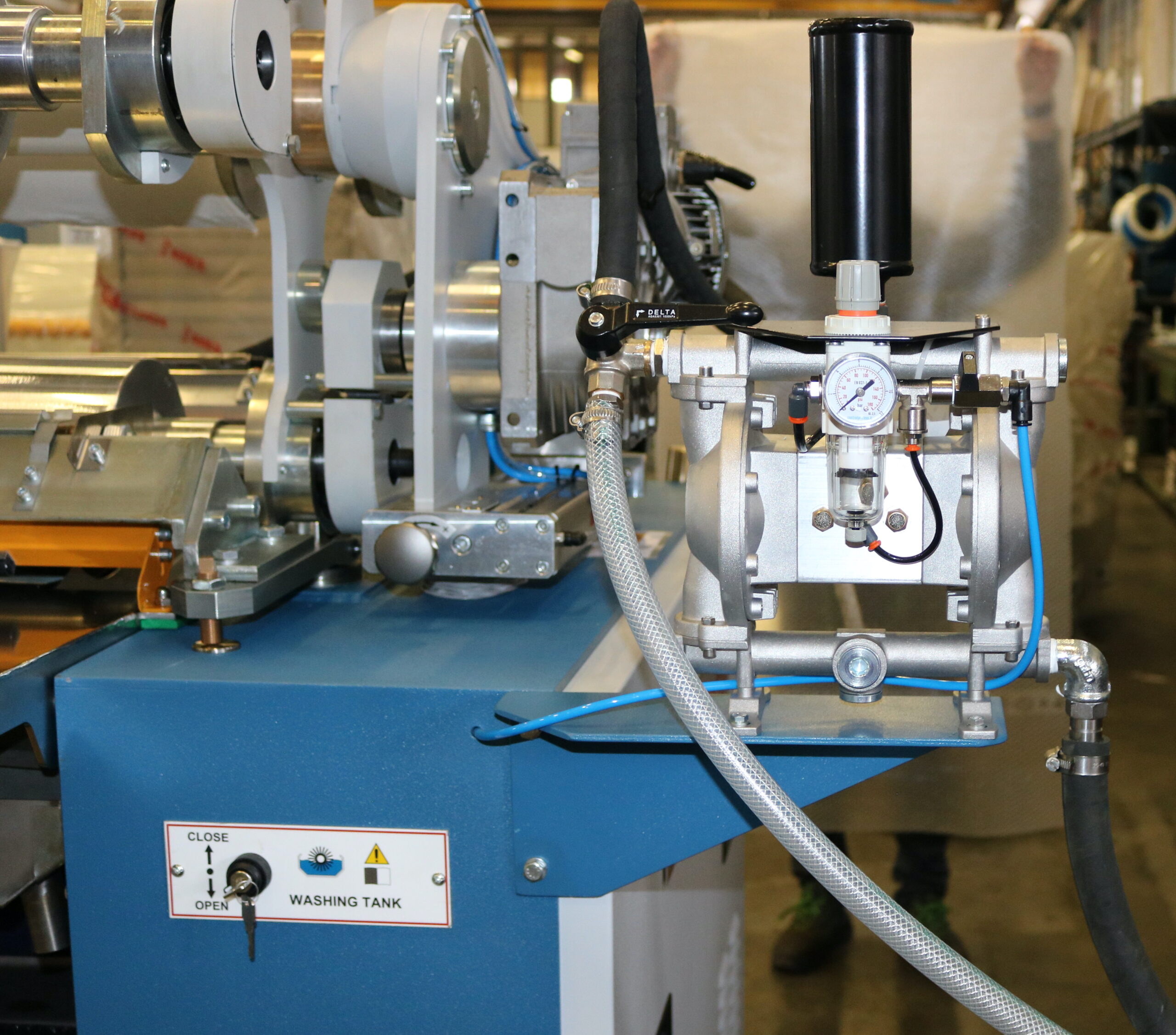

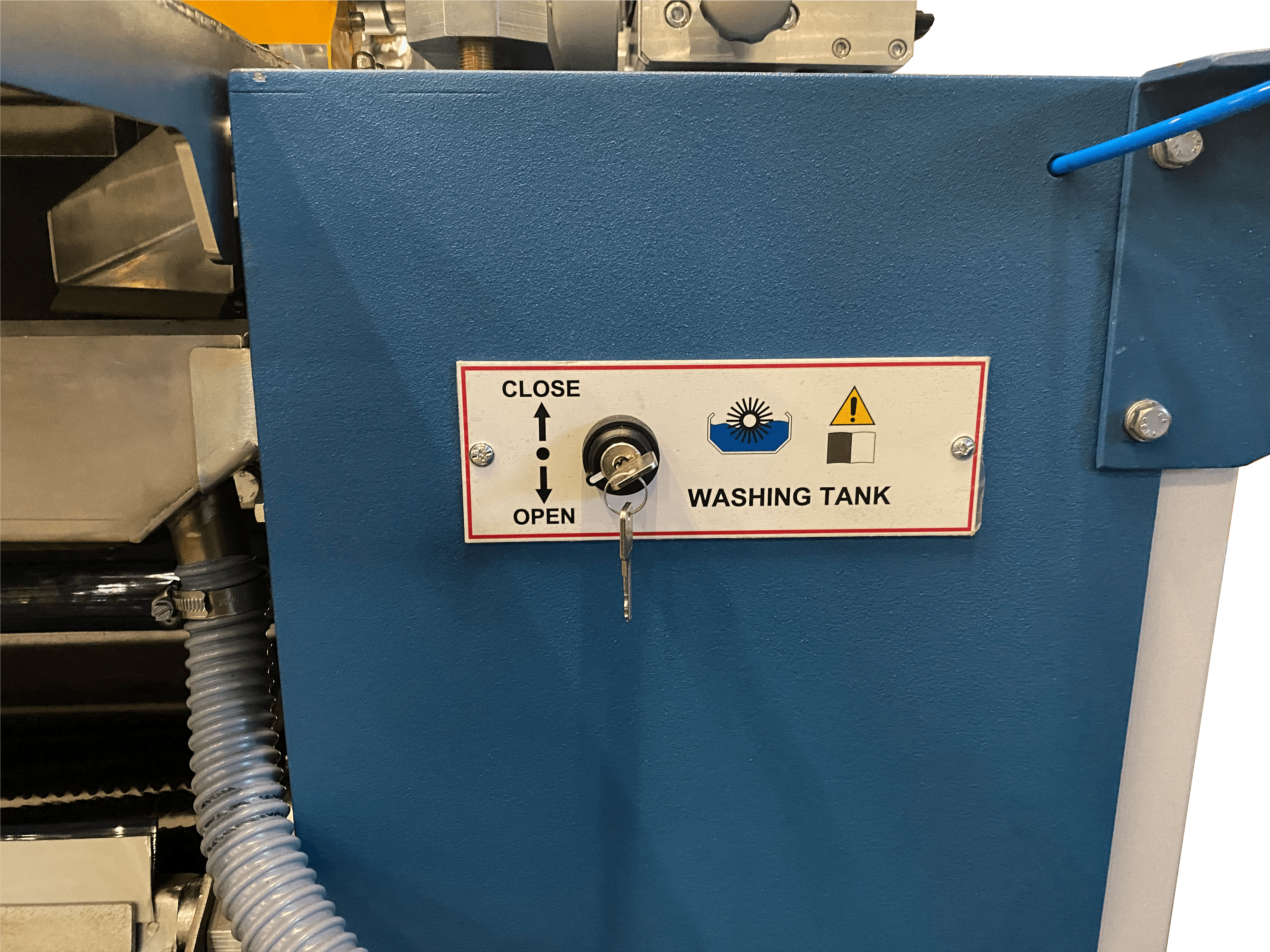

Wide opening of the doctor blade for easier roller cleaning, easily removable washing tank, electric adjustment of the thickness of the working right and left independently, are just some of the technical details that distinguish this machine.

Sizes: 1000/1800/2200/2400/2600

| MODEL | MULTICOAT | 10 | 18 | 22 | 26 |

|---|---|---|---|---|---|

| Electric power without heating | kW | 4.5 | 4.5 | 6.5 | 6.5 |

| Electric power for heating only | kW | 6.0 | 6.0 | 6.0 | 6.0 |

| Weight with 3 rollers | kg | 1650 | 2150 | 2400 | 2650 |

| Overall dimensions | mm | 2600 x 1450 x 2000 h | 3400 x 1450 x 2000 h | 3800 x 1400 x 2000 h | 4200 x 1450 x 2000 h |

Tables, Rollers and Application Types

Rollers "HSS"

Engraved for deep and stucco

| Roller | Gr/Pq. | Application |

|---|---|---|

| 68HSS | 5-7 | Heavy defect leathers |

| 70HSS | 3-5 | Light defect leathers |

| 72HSS | 1.5-3 | Base coat on full-grain leathers |

| 74HSS | 1.5-3 | Base coat on full-grain leathers |

Tables, Rollers and Application Types

Truncated Pyramidal Rollers

| Cylinder "Reverse" | Capacity Gr/Pg | Application |

|---|---|---|

| 8/B 8/C | 33 - 40 27 - 35 | Coating with adhesive |

| 10/B 10/C | 24 - 33 18 - 27 | Heavy coatings on crusts |

| 20/B 20/C | 15 - 25 12 - 18 | Hot and cold greases Impregnations |

| 30/A 30/X | 10 - 16 8 - 12 | Coatings on crusts and grinds |

| 30/C 30/F | 5 - 10 3 - 6 | Refinements on grain Lacquer application |

| 40/F | 1 - 2.5 | Double tone (thousand points) on coarse grain |

Tables, Rollers and Application Types

Rollers "L"

Engraved for synchro

| Rullo | Portata Gr/Pg | Applicazione |

|---|---|---|

| 6L 8L | 14 - 18 12 - 16 | Resine e Colle |

| 10L 12L | 10 - 14 9 - 13 | Ingrassi a caldo e a freddo |

| 16L 20L 24L | 6-9 5-8 4-7 | Tinture all'anilina, leggere coperture su fiore e applicazioni di lacca |

| 32L 40L | 2-4 1 - 3 | Doppio Tono (millepunti) su grana grossa |

| 48L 60L | 1-2 1 | Doppio Tono (millepunti) su grana fine |

The Multicoat is equipped with many accessories on request, as can be seen in the adjacent table. The choice of accessories depends on the type of use that the operator has to make, and for greater knowledge, the BERGI sfaff is available for consultation. Multicoat is suitable for many types of leather and processes, with the exception of very soft and unstructured leathers.

Bergi S.p.A.

Via Montorso 4/A,

36071 Arzignano, VI, Italy

CF/P.IVA 01277430243

REA VI-158023

Reg. Imp. VI-01277430243

M. VI-005517

Cap. soc. € 1.000.000,00 int. vers.

© 2024 Bergi S.p.A. | All Rights Reserved