Back to: Polishing machines

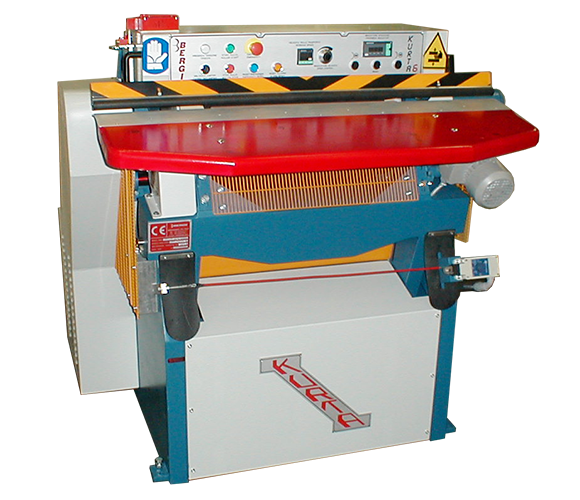

Roller polishing machine

Roller polishing machine Roller polishing machine. In sizes 600 and 800 mm it is ideal for sheep and goats, calves and other small leathers, while in sizes 1200, 1500, 1800, 2200 and 3000 mm it is ideal for whole or half leathers of different sizes.

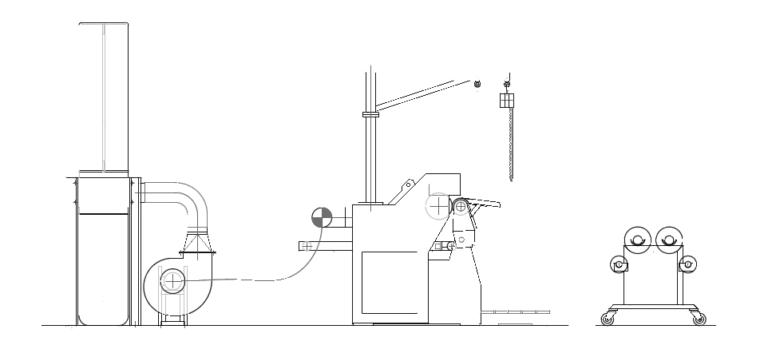

The advantage of working with a polishing machine of the correct size is that it polishes the leather in a single pass, thus avoiding the marks of the repeated processing, which can be noticed against the light; furthermore it is possible to work in continuous, in line with a dedusting machine or an automatic stacker.

Sizes: 600 / 800 / 1200 / 1500 1800 / 2200 / 3000

| MODEL | KURTA | 6 | 8 | 12 | 15 | 18 | 22 | 30 |

|---|---|---|---|---|---|---|---|---|

| Usable Width | mm | 600 | 800 | 1200 | 1500 | 1800 | 2200 | 3000 |

| Working Speed | m/min | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 |

| Total Power | kW | 8 | 12.5 | 16 | 18 | 20 | 23 | 34 |

| Compressed Air Pressure | bar | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Suction Air Volume | m3/h 250 Kgf/m2 | 30 | 35 | 40 | 45 | 50 | 55 | 60 |

| Net Weight of Base Model | from N (kg) | 1050 | 1200 | 1470 | 2650 | 3350 | 4480 | 7100 |

| Gross Weight | from N (kg) | 1370 | 1580 | 1950 | 3160 | 4060 | 4800 | 8200 |

| Base Model Dimensions | mm | 1550 x 1400 x 1470 h | 1700 x 1400 x 1470 h | 2100 x 1970 x 1470 h | 2700 x 2100 x 1550 h | 3000 x 2100 x 1550 h | 3400 x 2100 x 1550 h | 4300 x 2280 x 1700 h |

Aware of its responsibilities, Bergi joined the “Supplier of Sustainable Technologies” project promoted by Assomac in 2017, with the aim of contributing to deepening the key issues related to the intelligent and conscious management of energy, water, and natural resources, with the perspective of qualifying the manufacturing industry’s production process as sustainable.

The focal point of the project is the “Green Label,” a voluntary declaration certifying the energy and environmental performance of machines, calculated based on internationally recognized parameters such as the CFP (Carbon Footprint, the amount of equivalent carbon dioxide emissions) measured using the shared and standardized Life Cycle Assessment (LCA) calculation methodology.

S (600/800/1200)Buffing roller with wrapped paper and automatic paper tensioning system. This roller is supplied with an oscillator and rubber transport roller with physical characteristics and hardnesses chosen in cooperation with the customer to suit each type of processing.

PL (600/800/1200/1500/1800/2200/3000) V-shaped grooved green wool cloth polish roller. The inclined grooves guarantee a well spreading of the leather and an opening of the follicle for perfect cleaning. It is used in the intermediate stage to remove small defects and chemical impurities from the leather and is ideal for oiled and waxed leather. The green wool cloth roller can be manufactured in three different hardnesses (soft, medium, hard). The transport roller made of sandblasted and chrome-plated steel is supplied with this roller.

WW (600/800/1200/1500/1800/2200/3000)V-shaped grooved white wool cloth polish roller. The inclined grooves guarantee a well spreading of the leather and an opening of the follicle for perfect cleaning. The inclined grooves guarantee a well spreading of the leather and an opening of the follicle for perfect cleaning. It should be used in the final stage for polishing, as it has no warp and weft so it does not strip the skins. The transport roller made of sandblasted and chrome-plated steel is supplied with this roller.

C (600/800/1200/1500/1800) Channel-free cotton cloth roller made of cotton discs placed side by side. The discs are left soft for the application of the “carnauba” wax and the roller is equipped with a special support for the application and the dosage, through an external handle, of the wax. It is used in the final stage to obtain the “brush-off” effect on the finished leather. The transport roller made of sandblasted and chrome-plated steel is supplied with this roller.

Bergi S.p.A.

Via Montorso 4/A,

36071 Arzignano, VI, Italy

CF/P.IVA 01277430243

REA VI-158023

Reg. Imp. VI-01277430243

M. VI-005517

Cap. soc. € 1.000.000,00 int. vers.

© 2024 Bergi S.p.A. | All Rights Reserved