Back to: Roller coating machines

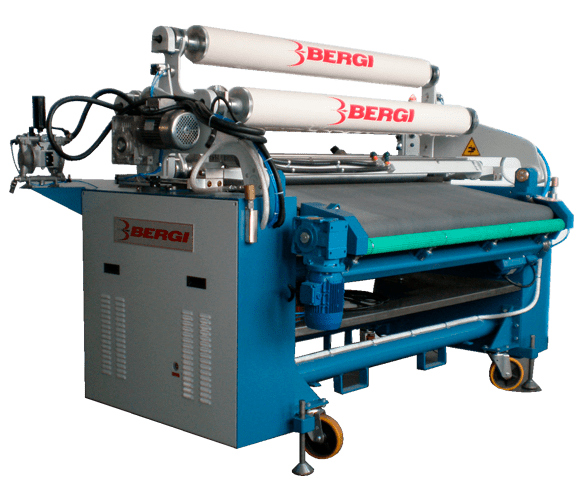

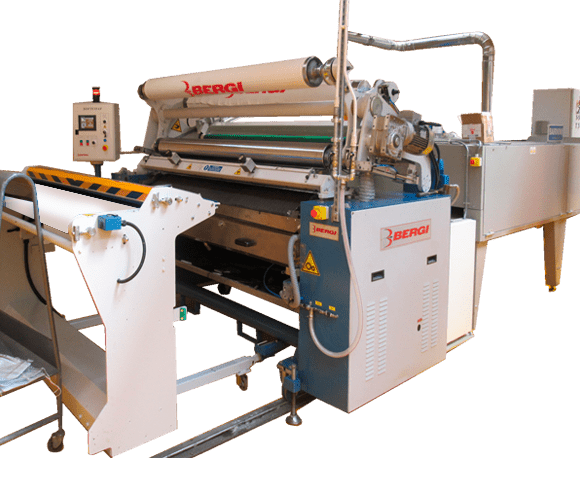

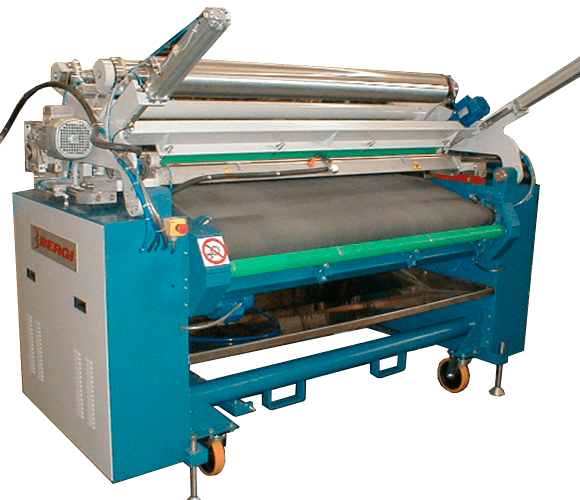

Roller coating machine for soft leathers.

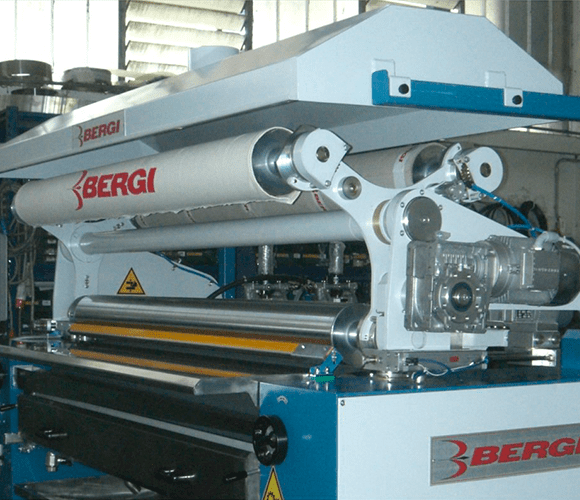

The roller coating machine Softcoat is the latest version of roller coater by Bergi S.p.a. Totally renewed, the Softcoat is ready to challenge all its competitors. Specific test trials have demonstrated the high qualitative performances both in reverse and synchro (direct) operative modes, now standard devices of the machine.

Sizes: 1000/1800/2200/2400/2600/3400

| MODELLO | SOFTCOAT | 10 | 18 | 22 | 26 |

|---|---|---|---|---|---|

| Weight with 3 rollers | Kg | 1850 | 2350 | 3050 | 3550 |

| Electrical power only for heating | Kw | 6.0 | 6.0 | 6.0 | 6.0 |

| Electrical power absorbed without heating | Kw | 5.6 | 5.6 | 7.6 | 7.6 |

| Overall dimensions with spreader open | mm | 2600 x 2800 x 2000 h | 2600 x 2800 x 2000 h | 2600 x 2800 x 2000 h | 2600 x 2800 x 2000 h |

| Overall dimensions with spreader closed | mm | 2600 x 2000 x 2000 h | 3400 x 2000 x 2000 h | 3800 x 2000 x 2000 h | 4200 x 2000 x 2000 h |

Tables, Rollers, and Types of applications

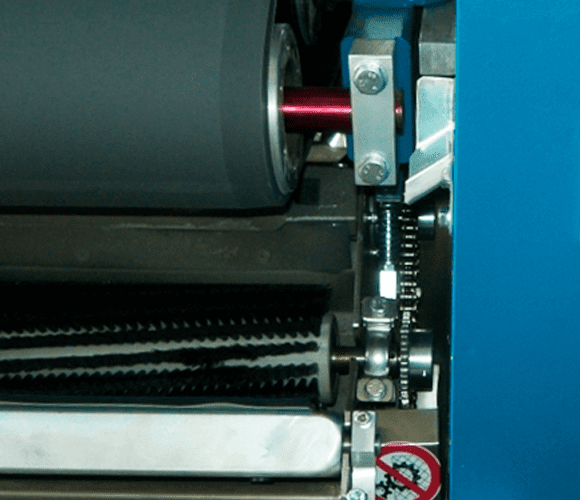

Engraved rollers for basecoat and filler

| Roll | Load Gr/sq | Application |

|---|---|---|

| 68HSS | 5-7 | Leathers with heavy defect |

| 70HSS | 3-5 | Leathers with light defect |

| 72HSS | 1,5-3 | Base coat on full-grain leathers |

| 74HSS | 1,5-3 | Base coat on full-grain leathers |

Tables, Rollers, and Types of applications

Engraved rollers for bottom, top, oil

| Rolls | Load Gr/sq | Application |

|---|---|---|

| 68HS | 15 - 25 | Impregnation |

| 70HS | 12 - 20 | Impregnation |

| 72HS | 8 - 15 | Medium Coatings |

| 74HS 76HS | 6-12 5-9 | Light Coatings |

| 78HS 80HS | 2 - 6 1- 2 | Grain Finishing - Lacquer Application |

Tables, Rollers, and Types of applications

Engraved rolls for synchro

| Rolls | Load Gr/sq | Application |

|---|---|---|

| 6/L 8/L | 14 - 18 12 - 16 | Resins and Glues |

| 10/1 12/L | 10 - 14 9- 13 | Hot and Cold Greases |

| 16/L 20/L 24/L | 6-9 5-8 4-7 | Aniline dyes, light top coats on grain and lacquer applications |

| 32/L 40/L | 2-4 1 _ 3 | Two-tone (thousand-point) on coarse grain |

| 48/L 60/L | 1-2 1 | Two-tone (thousand-point) on fine grain |

The softcoat can be equipped with many option accessories to carry out different types of working processes.

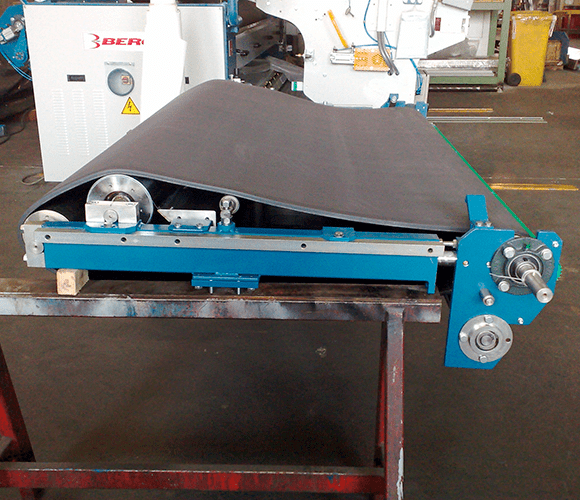

The Softcoat can be equipped with a transport conveyor to connect the machine to the drying tunnel. The “tip-up” model is vertically liftable to create the necessary space for maintenance and cleaning without moving the equipments.

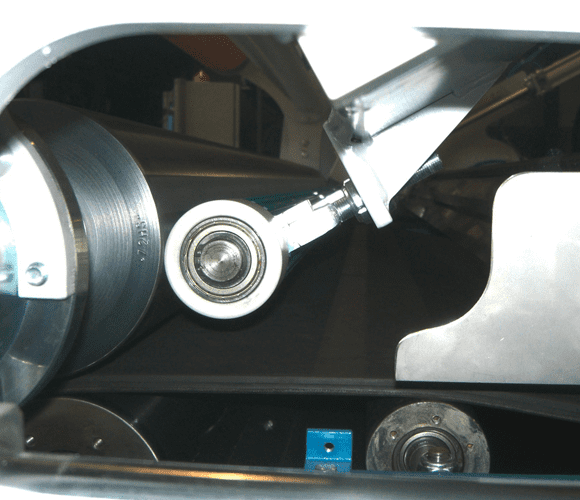

The Softcoat is equipped with wheels and rails to be easily moved in case it is necessary. The Softcoat has been designed to be easy to clean at the end of each productive cycle. In fact, a good cleaning keeps the machine at the maximum efficiency.

Bergi S.p.A.

Via Montorso 4/A,

36071 Arzignano, VI, Italy

CF/P.IVA 01277430243

REA VI-158023

Reg. Imp. VI-01277430243

M. VI-005517

Cap. soc. € 1.000.000,00 int. vers.

© 2024 Bergi S.p.A. | All Rights Reserved