Back to: Roller coating machines

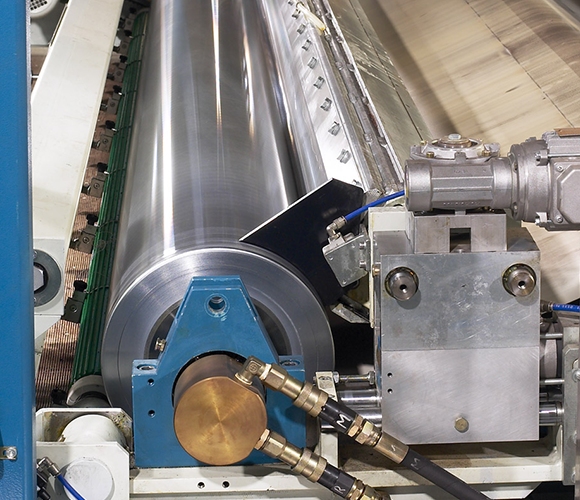

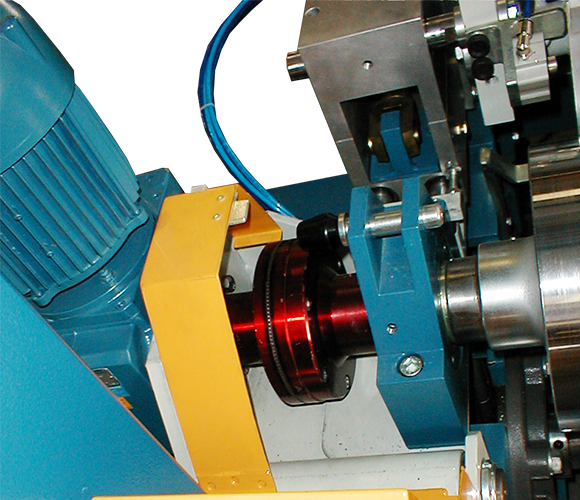

The SYNCHROCOAT is a machine for applying “thousand-dot” effects and designs on large whole hides. Unlike the competition, the SYNCHROCOAT is only manufactured with a winch-type roller change. This very important choice was made because this system allows the transmission motor to be connected to the operator roller via two gears with front teeth, which eliminates any play between the parts. This system ensures the design is transferred onto the hides with maximum precision.

The SYNCHROCOAT is a roller machine designed for two-tone effects on finished furniture and interior leather.

The machine is equipped with a winch with 5 or more positions. The operator roller can be of various types depending on the processing:

Inverted pyramid of various sizes for applying oils, waxes on grain, or aroma or a fixative to stop the fiber from the flesh side.

Engraved rollers for cloudy effects, aged looks, imitation of grains like faux flowers, exotic animals, etc.

Sizes: 3400

| MODEL | ROTOINCO | 34 |

|---|---|---|

| Useful Width | mm | 3400 |

| Installed Power Machine | Kw | 7 |

| Installed Power POD | Kw | 7 |

| Installed Power Heating | Kw | 18 |

| Working Speed | m/min | 5 ÷ 15 |

| Machine Weight with 3 Rolls | Kg | 8250 |

| Net Weight of an Operator Roll | Kg | 1800 |

| Machine Dimensions Rotary | mm | 5600 x 2500 x 2800 h |

| Machine Dimensions Hoist | mm | 5600 x 4400 x 2800 h |

| Machine Dimensions Rotary and POD | mm | 5600 x 4600 x 3600 h |

| Machine Dimensions Hoist and POD | mm | 5600 x 4600 x 3600 h |

Bergi S.p.A.

Via Montorso 4/A,

36071 Arzignano, VI, Italy

CF/P.IVA 01277430243

REA VI-158023

Reg. Imp. VI-01277430243

M. VI-005517

Cap. soc. € 1.000.000,00 int. vers.

© 2024 Bergi S.p.A. | All Rights Reserved