Back to: Automation and handling

Special compact-type stacker with split movable conveyor.

The stacker BERTECH model ARMLESS is the machine specifically developed to meet the needs of the finishing plant where in the same line both full hides and sides are processed.

This stacker is also useful for those tanneries that process small size leathers such as croupons, shoulders, sheep & goat skins on large machines (such as spray lines or ironing machines) and deposit the leathers on two stacks.

The name of the ARMLESS derives from the fact that this stacker is without arms since it is made of two movable, independent and self-standing conveyors that, when necessary, can work as a single one. A specific software allows the two conveyors to move either independently or perfectly paired and synchronized. Built following the highest quality standards, the stacker ARMLESS has a strong and solid structure made of materials that have been tested in tannery through long and intense productive cycles and its dimensions place it among the most compact machine of its category.

BERTECH is the sole manufacturer that equips its stackers ARMLESS and DYNAMIC of the anti-fall system of the lifting device considering it essential for the safety of the machine and operators.

Sizes: 2200/2600/3200/3400

| MODEL | ARMLESS | 20 | 22 | 26 | 32 | 34 |

|---|---|---|---|---|---|---|

| Installed Power | Kw | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 |

| Machine Weight | Kg | 2100 | 2200 | 2330 | 2450 | 2550 |

| Overall Dimensions | mm | 3160 x 4800 x 2585 h | 3400 x 4800 x 2585 h | 3840 x 4800 x 2585 h | 4360 x 4800 x 2585 h | 4600 x 4800 x 2585 h |

| Transport Dimensions | mm | 3070 x 2000 x 2300 h | 3310 x 2000 x 2300 h | 3750 x 2000 x 2300 h | 4270 x 2000 x 2300 h | 4510 x 2000 x 2300 h |

After staking machine – STK with brush extractor (if not supplied with the staking machine)

After Dedusting machine – DD without extractor (with brush extractor un case of leather loaded with electrostatic electricity)

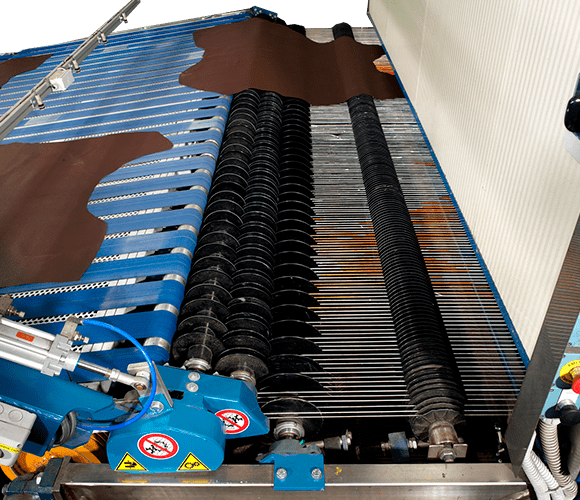

After finishing line – SPR with discs extractor

After ironing machine – FPR with brush extractor

After measuring machine – MM without extractor

S = short: for trestle storage of long hides or board for medium/short hides (maximum stroke 1600 mm).

Bergi S.p.A.

Via Montorso 4/A,

36071 Arzignano, VI, Italy

CF/P.IVA 01277430243

REA VI-158023

Reg. Imp. VI-01277430243

M. VI-005517

Cap. soc. € 1.000.000,00 int. vers.

© 2024 Bergi S.p.A. | All Rights Reserved